The product production process can be carried out as follows:

The first step: pre-sales service

Based on the information provided by the customer, we will conduct proofing and plan production. We work closely with our customers to ensure we understand their needs and provide solutions that meet their requirements.

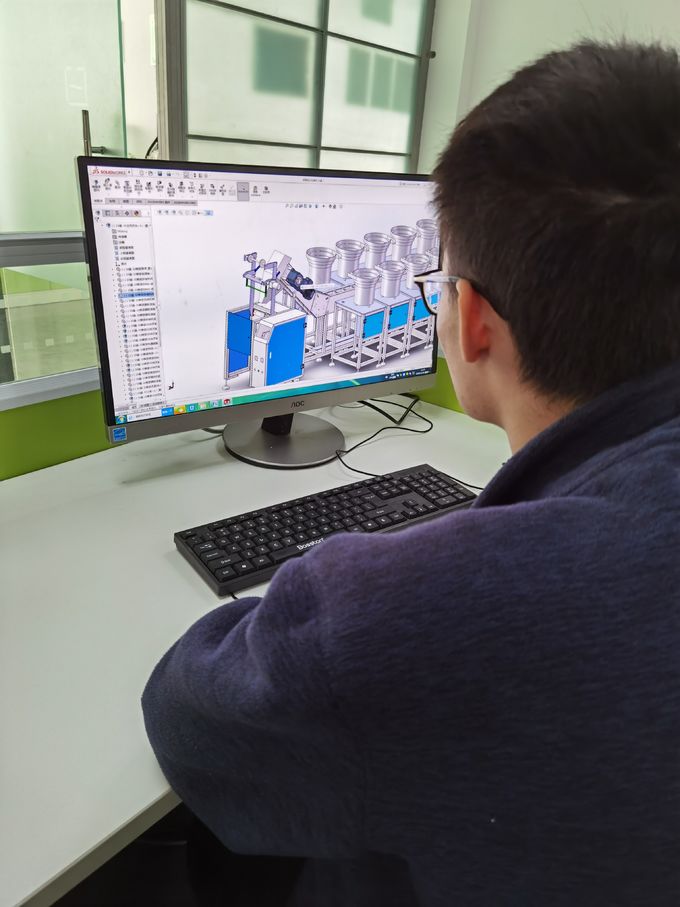

Step Two: Production Progress

According to the task order, we will produce and the production progress will be tracked by a dedicated salesperson. They will report production progress to customers at any time to ensure that customers understand the progress of the project.

Step 3: Shipping

The quality control team will conduct pre-shipment inspections according to the production task order to ensure that every link meets the requirements. They will make final confirmation according to the samples and customer's requirements to ensure the quality and accuracy of the product.

Step 4: Packaging and shipping

According to the customer's type and requirements, we will carry out appropriate packing and packaging, and agree on the delivery method with the customer. We will ensure that the product is fully protected during transportation to ensure that the product reaches the customer in good condition.

Step 5: After-sales service

We provide online technical installation guidance to ensure customers can use our products correctly. Our team will communicate and guide customers to answer questions they may have and ensure they are taking full advantage of the product's features.

Step 6: Post-maintenance

Our salespeople will regularly visit customers to learn about their use of the product, and follow up on subsequent needs and assistance raised by customers. We will always keep in touch with our customers to ensure they receive satisfactory products and services and meet their future needs.

Through the above product production process, we are committed to providing customers with high-quality products and comprehensive services to ensure customer satisfaction and establish long-term cooperative relationships.